We help you install, maintain, and upgrade your electrical systems to save you time and money while protecting your people and investment.

Commercial Electrician Serving the Entire State of Georgia

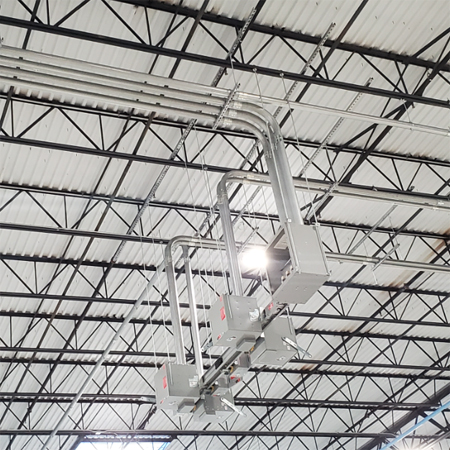

Electrical Trailer Refrigeration Install

EV Charging Station Install

Equipment Maintenance/Testing

Electrical

Services

Power System

Studies

Focus on Your Core Business and We’ll Keep Your Electrical Systems Running Smoothly & Decrease Costs

Manufacturing & Industrial

Commercial

You Deserve a Certified Industrial & Commercial Electrical Contractor You Can Trust To Protect Your People & Investment

Why Craft Electric & Maintenance?

Craft Electric & Maintenance has served Atlanta, North and Middle Georgia since 1984. We have earned a reputation for superior quality construction through integrity and hard work. Our commitment to safety, professional competence, and customer satisfaction sets the standard for all other electrical contractors. We have a long list of repeat customers due to honest approach and record of successful projects.

Whether installing from the ground up, maintaining, or upgrading the electrical system, Craft Electric & Maintenance will strive to meet and surpass your needs. We approach each client with the specific intent of creating trust. By consistently performing in a manner that distinguishes us from our competition, we demonstrate our planning expertise, provide the service we promised, and prove that our client is the most important member of the team.