Electrical Power System Studies

Craft Electric & Maintenance Specializes in Electrical Power System Studies

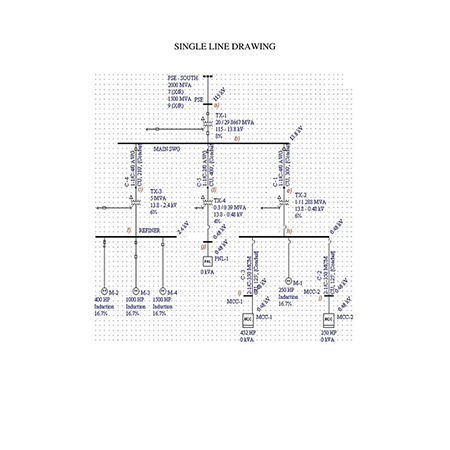

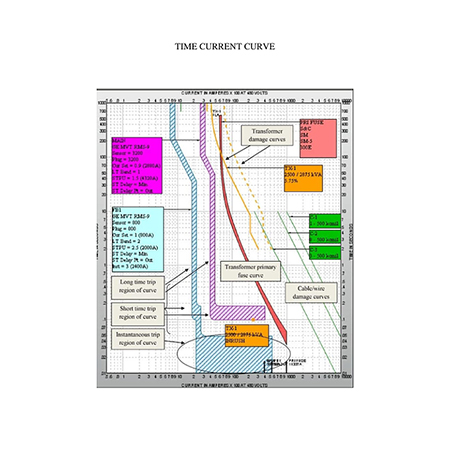

When you need electrical power system studies performed in your facility, you can trust our Craft Electric & Maintenance team to provide high-quality, dependable results every time. We conduct arc flash hazard studies, electrical short circuit studies, electrical coordination studies, and power quality and mitigation services. We have extensive experience performing electrical power system studies in industrial and commercial settings. You can feel confident that we can keep your employees safe and your equipment running at full capacity.Arc Flash Hazard

Studies

Electrical Short Circuit

Studies

Electrical Coordination

Studies

Power Quality &

Mitigation