What Is Thermographic Imaging of Electrical Systems?

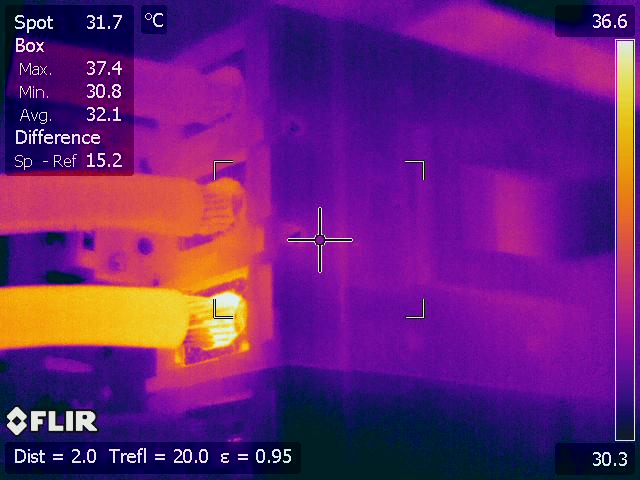

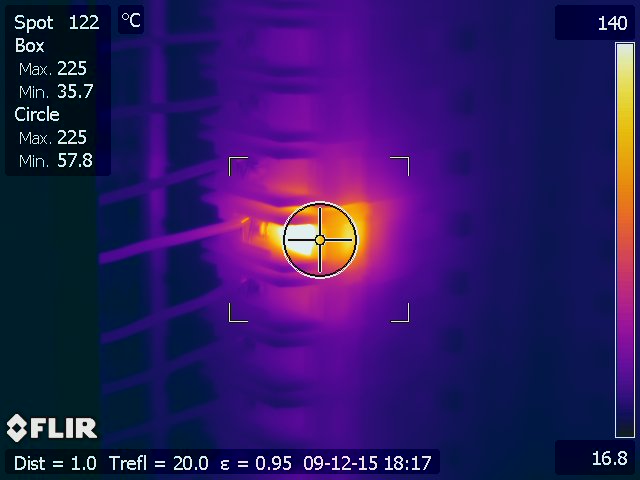

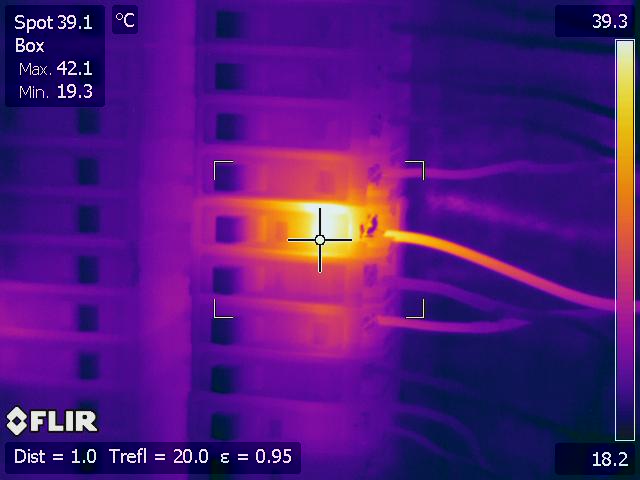

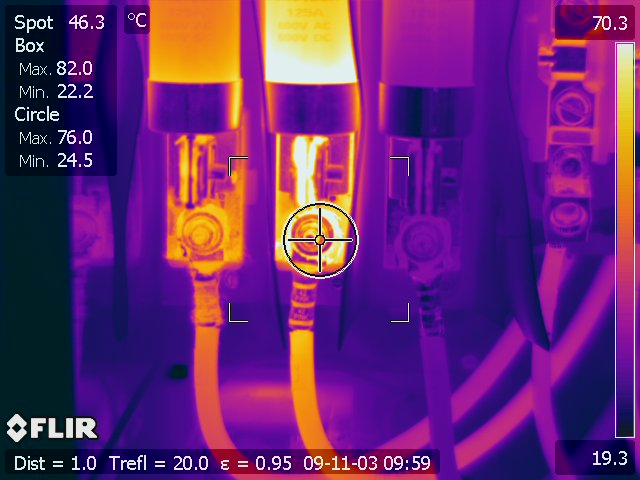

Thermographic Imaging utilizes an (IR) Infrared Camera to identify heat anomalies associated with electrical equipment and component failure. Heat is generated due to problems such as loose connections, failing electrical components, and overloading conditions. By obtaining heat distribution pictures, it's possible to get an idea about the state of the equipment and whether it is in a stage of malfunctioning. There are a variety of different reasons that would indicate a temperature rise. For example, problems such as loose connections, failing electrical components, and overloading conditions generate heat. Thermographic imaging helps us identify heat patterns so we can pinpoint the cause of the problem and provide a quick solution to avoid serious issues.

Why Is Thermographic Imaging Important?

Thermographic imaging is important because if not identified and corrected, heat-related anomalies can lead to equipment failure and fire. Often, equipment failure can be catastrophic and cause serious injury or death as well as unscheduled downtime, which translates into lost revenue.

It is essential to understand thermographic imaging is a diagnostic tool and is primarily used to identify heat-related anomalies. All problems associated with electrical equipment do not always produce heat, so other forms of troubleshooting may be necessary.

How Can Craft Electric & Maintenance Help With Thermographic Imaging?

Our trained thermographers identify trouble before it becomes a major problem associated with costly downtime. Craft Electric and Maintenance utilizes thermographic imaging to provide a greater level of confidence in all phases of your maintenance and production operations. We provide:

- An onsite assessment to determine which equipment to target for the Infrared Thermography Service

- Level 2 thermographers trained in the use of Infrared Technology

- A detailed report to the customer that outlines all anomalies discovered, root cause analysis, and recommendations for corrective action

For more information on thermographic imaging, please click the button below to speak with an expert.

What Type of Thermographic Imaging Reporting

Do We Provide?

NFPA 70E, Article 205.3 states: Electrical equipment shall be maintained in accordance with the manufacturer’s instructions or industry consensus standards to reduce the risk associated with failure. The equipment owner or owner’s designated representative shall be responsible for maintenance of the electrical equipment and documentation.

Craft Electric & Maintenance generates documentation of their findings and recommendations for corrective action. We use various maintenance and testing methods based on recommended industry standards.

Why Choose Craft & Electric Maintenance for Thermographic

Imaging?

Craft Electric & Maintenance has the experience necessary to help move your project forward and strictly complies with the national electrical code. We are NFPA 70E compliant for electrical safety in the workplace. We will not put your company and staff at risk or our employees.

We ALWAYS follow current NFPA 70B standards or industry best practices. We have technicians properly trained in the use of infrared technology, and we are ready to help you when you need it most. We offer 24/7 emergency service to existing clients. We understand that you often need a quick response for services, and we strive for a one-week turnaround on proposals.

You Deserve A Certified Industrial & Commercial Electrical Contractor to Protect Your People & Investment